Silsiladda Isku xirka Macdanta Wareega ee Saddexda Ring

Silsiladda Isku xirka Macdanta Wareega ee Saddexda Ring

Soo bandhigida Seddexda Ring Round Mining Link Chain, oo ah badeeco kacaan ah oo loogu talagalay in lagu daboolo baahiyaha baahida warshadaha macdanta. Silsiladdan cirifka ah ayaa loo habeeyey si ay u bixiso xoog, adkeysi iyo isku hallayn aan la qiyaasi karin ee hawlaha macdanta ee ugu adag.

Silsilad macdaneed wareeg ah oo saddex giraan ah ayaa loogu talagalay codsiyada macdanta halkaasoo culeysyo culus iyo xaalado daran ay caadi yihiin. Naqshadeeda gaarka ah ee saddexda giraanta ah waxay hubisaa qaybinta miisaanka ugu fiican, yaraynta diiqada isku-xirnaanta shakhsi ahaaneed iyo hagaajinta waxqabadka guud. Naqshaddan cusubi sidoo kale waa sahlan tahay in la ilaaliyo, maaddaama xiriiriyeyaasha dhaawacan ama xiran ay si fudud u beddeli karaan iyada oo aan saameyn ku yeelan shaqeynta silsiladda oo dhan.

Silsilada macdanta wareega ee saddex-xiran ayaa laga dhisay qalab tayo sare leh oo leh awood cufan oo gaar ah si ay ugu adkeystaan adkaanta deegaanka macdanta. Habka dhuujinta ee aadka loo ilaaliyo wuxuu bixiyaa xiriir la isku halayn karo oo ka dhexeeya silsiladda iyo qalabka macdanta, yaraynta khatarta shilalka iyo kordhinta wax soo saarka.

Intaa waxaa dheer, silsiladdu waxay leedahay iska caabin aad u fiican, iyada oo hubinaysa cimrigeeda dheer xitaa meelaha macdanta ugu adag. Dhismaheeda adag wuxuu dammaanad qaadayaa jeexjeexa iyo jeexjeexa ugu yar, hoos u dhigista wakhtiga dayactirka iyo beddelka, ugu dambeyntii kordhinta waxtarka iyo badbaadinta kharashyada.

Silsilada macdanta wareegta ah ee saddex-geesood ah waxay mudnaanta siinayaan xoogga iyo cimri dhererka, laakiin sidoo kale badbaadada. Waxa ay mareen tijaabo badan si loo hubiyo in ay u hoggaansanto dhammaan heerarka amniga iyo xeerarka khuseeya warshadaha macdanta. Isticmaalka silsiladan, hawl-wadeennada macdanta waxay ku raaxaysan karaan xasilloonida maskaxda iyagoo og in alaabada ay isticmaalayaan ay la kulmaan xeerarka badbaadada ee ugu adag.

Marka la soo koobo, silsiladda isku xirka macdanta wareegta ee 3-ring ayaa ah xalka ugu dambeeya ee xirfadlayaasha macdanta raadinaya silsilad la isku halleyn karo, xoog leh oo ammaan ah hawlahooda. Naqshadeeda gaarka ah, xoogga gaarka ah iyo iska caabbinta daxalka ayaa ka dhigaya doorasho aad u fiican warshadaha macdanta. Maalgelinta 3-Ring Mining Link Chain maanta si aad u wanaajiso hawlahaaga macdan qodista!

Qaybta

Silsiladda isku xirka wareega, silsilad isku xirka birta wareega, silsilada isku xirka macdanta wareega, DIN 22252silsilad macdanta, silsilad conveyor macdanta, nidaamka silsilad bar duulimaadka

Codsiga

Gawaadhida Wajiga Gaashaan (AFC), Beam Stage Loaders (BSL), mashiinada madaxa wadada, jeexyada dhuxusha, iwm.

Sida No. 1 dalka wax soo saarka dhuxusha, Shiinaha ayaa arkay baahida loo qabo tiro weyn oo wareeg ah silsiladaha macdanta isku xidha, oo sidaas ayaa dhiiri Shiinaha wareeg ah awoodda wax soo saarka silsilad birta ah marka la eego tirada iyo tayada. Warshada silsiladda SCIC oo leh 30 sano oo silsilad silsilado bir ah oo wareeg ah taariikhda wax soo saarka ayaa si buuxda ugu lug lahayd sahayda warshadaha dhuxusha ee Shiinaha; Silsiladayada isku xirka wareega ah ayaa ilaa hadda si wanaagsan loo aqbalay oo ay isticmaaleen dhammaan shirkadaha dhuxusha & macdanta ee Shiinaha.

Tayada silsiladeena isku xirka birta wareega ah waxaa lagu hubiyaa tillaabo kasta oo wax soo saarka silsiladda, laga bilaabo baararka birta daawaha ee dhawaaqa si sax ah loo sameeyo isku xirka robot, laga bilaabo alxanka dabada kombuyuutarka ilaa si fiican loo demiyo & kuleylka kuleylka-daawaynta (taasoo keentay xoogga la doonayo iyo adkaanta dusha sare), laga bilaabo tijaabada caddaynta ilaa tijaabooyinka farsamada ee xaqiijinta tayada gudaha iyo sare.

Silsiladda wareegga wareegga SCIC waxaa loo sameeyay iyadoo loo eegayo heerka Shiinaha GB/T-12718 iyo Shuruudaha Farsamo ee warshadda, iyo sidoo kale DIN 22252 ama GOST 25996 heerarka iyo macaamiisha macaamiisha.

Silsiladda isku xirka wareega wareega ee SCIC waxaa loo adeegsadaa Conveyors Wajiga Gaashaan (AFC), Beam Stage Loaders (BSL), mashiinada madaxa wadada, jeexyada dhuxusha iyo qalabka kale ee u baahan silsilad noocan ah.

Dahaarka ka-hortagga daxalka (tusaale, galvanization kulul) waxay keenaysaa hoos u dhaca guryaha makaanikada ah ee silsiladda, sidaa darteed codsashada dahaar kasta oo ka-hortagga dahaadhku waa in ay amar ku bixiyaan heshiis u dhexeeya iibsadaha iyo SCIC.

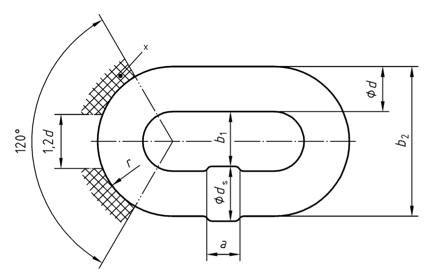

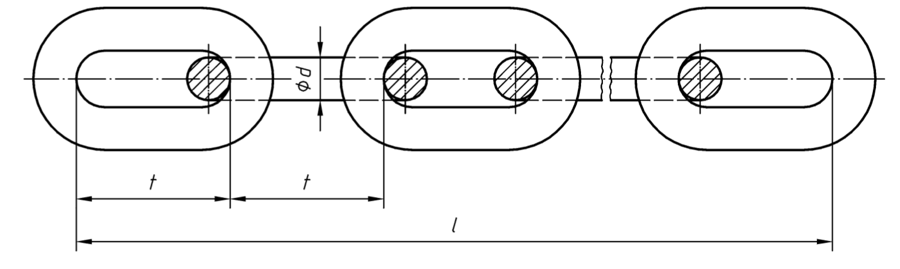

Jaantuska 1: silsilad isku xidhka wareega

Shaxda 1: cabbirka silsiladda isku xirka wareega

| cabbirka isku xirka (opp. Weld) | garoonka | ballaca isku xirka | cabbir alxanka link | miisaanka halbeegga | ||||

| magac ahaan | dulqaadasho | magac ahaan | dulqaadasho | gudaha | dibadda | dhexroorka | dhererka | |

| 10 | ± 0.4 | 40 | ±0.5 | 12 | 34 | 10.8 | 7.1 | 1.9 |

| 14 | ± 0.4 | 50 | ±0.5 | 17 | 48 | 15 | 10 | 4.0 |

| 18 | ± 0.5 | 64 | ±0.6 | 21 | 60 | 19.5 | 13 | 6.6 |

| 19 | ± 0.6 | 64.5 | ±0.6 | 22 | 63 | 20 | 13 | 7.4 |

| 22 | ± 0.7 | 86 | ±0.9 | 26 | 74 | 23.5 | 15.5 | 9.5 |

| 24 | ± 0.8 | 86 | ±0.9 | 28 | 79 | 26 | 17 | 11.6 |

| 26 | ± 0.8 | 92 | ±0.9 | 30 | 86 | 28 | 18 | 13.7 |

| 30 | ± 0.9 | 108 | ±1.1 | 34 | 98 | 32.5 | 21 | 18.0 |

| 34 | ± 1.0 | 126 | ±1.3 | 38 | 109 | 36.5 | 23.8 | 22.7 |

| 38 | ± 1.1 | 126 | ±1.3 | 42 | 121 | 41 | 27 | 30.1 |

| 38 | ± 1.1 | 137 | ±1.4 | 42 | 121 | 41 | 27 | 29.0 |

| 42 | ± 1.3 | 137 | ±1.4 | 48 | 137 | 45 | 30 | 36.9 |

| 42 | ± 1.3 | 146 | ±1.5 | 48 | 137 | 45 | 30 | 36.0 |

| 42 | ± 1.3 | 152 | ±1.5 | 46 | 133 | 45 | 30 | 35.3 |

| qoraalo:LSilsiladda cabbirka anger waa la heli karaa marka la weydiiyo. | ||||||||

Shaxda 2: silsilad isku xirka wareegyada guryaha farsamada

| cabbirka silsiladda | darajada silsiladda | xoog tijaabi | elongation hoos xoogga imtixaanka | xoog jabin | elongation at jab | leexashada ugu yar |

| 10 x 40 | S | 85 | 1.4 | 110 | 14 | 10 |

| SC | 100 | 1.6 | 130 | |||

| SCC | 130 | 1.9 | 160 | |||

| 14 x 50 | S | 150 | 1.4 | 190 | 14 | 14 |

| SC | 200 | 1.6 | 250 | |||

| SCC | 250 | 1.9 | 310 | |||

| 18 x 64 | S | 260 | 1.4 | 320 | 14 | 18 |

| SC | 330 | 1.6 | 410 | |||

| SCC | 410 | 1.9 | 510 | |||

| 19 x 64.5 | S | 290 | 1.4 | 360 | 14 | 19 |

| SC | 360 | 1.6 | 450 | |||

| SCC | 450 | 1.9 | 565 | |||

| 22 x 86 | S | 380 | 1.4 | 480 | 14 | 22 |

| SC | 490 | 1.6 | 610 | |||

| SCC | 610 | 1.9 | 760 | |||

| 24 x 86 | S | 460 | 1.4 | 570 | 14 | 24 |

| SC | 580 | 1.6 | 720 | |||

| SCC | 720 | 1.9 | 900 | |||

| 26 x 92 | S | 540 | 1.4 | 670 | 14 | 26 |

| SC | 680 | 1.6 | 850 | |||

| SCC | 850 | 1.9 | 1060 | |||

| 30 x 108 | S | 710 | 1.4 | 890 | 14 | 30 |

| SC | 900 | 1.6 | 1130 | |||

| SCC | 1130 | 1.9 | 1410 | |||

| 34 x 126 | S | 900 | 1.4 | 1140 | 14 | 34 |

| SC | 1160 | 1.6 | 1450 | |||

| SCC | 1450 | 1.9 | 1810kii | |||

| 38 x 126 | S | 1130 | 1.4 | 1420 | 14 | 38 |

| SC | 1450 | 1.6 | 1810kii | |||

| SCC | 1810kii | 1.9 | 2270 | |||

| 42 x 137 | S | 1390 | 1.4 | 1740kii | 14 | 42 |

| SC | 1770kii | 1.6 | 2220 | |||

| SCC | 2220 | 1.9 | 2770 |