Silsiladda Isku Xidhka Bir-La'aanta ah ee Welded, Weeliyaha Wershadaha ee culayska culus leh/ Qaadista/Birta Daawaha/Birta Macdanta/ Macdanta Dhuxusha/ Macdanta/ Silsiladda Miinada

Silsiladda Isku Xidhka Bir-La'aanta ah ee Welded, Weeliyaha Wershadaha ee culayska culus leh/ Qaadista/Birta Daawaha/Birta Macdanta/ Macdanta Dhuxusha/ Macdanta/ Silsiladda Miinada

Soo bandhigida silsilada isku xidhka isku xidhka birta ah ee alxanka, xal culus oo loogu talagalay gudbinta warshadaha, qaadista iyo codsiyada macdanta. Silsiladdan wax-ku-oolka ah waxay ka samaysan tahay bir tayo sare leh oo daawaha ah, taas oo hubinaysa xoog sare iyo adkaysi.

Ku habboon jawiga warshadaha culus ee culus, silsiladahayaga isku xirka isku xirka birta ah ee welded waxay si fudud u maareyn karaan culeysyada macdanta, birta, macdanta dhuxusha iyo noocyo kala duwan oo hawlgalo macdan qodis ah. Dhismaheeda qallafsan iyo iska caabbinta daxalka ayaa ka dhigaysa doorasho la isku halayn karo oo wax looga qabanayo iyo gudbinta hufan.

Silsiladda waxaa loogu talagalay isku xirka alxanka ah ee xoogga ugu badan iyo dabacsanaanta loogu talagalay hawlo siman oo hufan. Xidhiidhada adag ayaa si adag isugu xidhan si loo helo waxqabad waara xataa marka lagu jiro xaalado aad u daran. Haddii aad u baahan tahay inaad dhaqaajiso culaysyo waaweyn, qaado alaab culus ama qalab kor u qaadis, silsiladahayaga birta ah ee alxanka leh ayaa qaban kara shaqada.

Qaybta

Nabadgelyadu waa mudnaanta koowaad ee jawi kasta oo warshadeed iyo silsiladaheennu waxay xaqiijinayaan hawlgal la isku halayn karo oo xasilloon. Silsiladda dhismaheeda waara waxay yaraynaysaa halista shilalka waxayna hubisaa jawi shaqo oo ammaan ah oo wax soo saar leh. Naqshaddeeda adag ayaa ka dhigaysa mid ku habboon xaaladaha adag, oo ay ku jiraan heerkul sare iyo culeysyo culus.

Intaa waxaa dheer, silsiladaheena birta ah ee alxanka leh waa kuwo adkaysi u leh oo u baahan dayactir yar. Tani waxay kuu badbaadinaysaa waqti iyo lacag maadaama dayactirka yar uu ka dhigan yahay wax soo saar badan iyo waqti-dhimis oo yar. Adkeysiga silsiladani waxay dammaanad qaadaysaa nolol adeeg dheer, taasoo ka dhigaysa ikhtiyaar qiimo leh oo mustaqbalka fog ah.

Waxaan fahamsanahay shuruudaha kala duwan ee macaamiisheena iyo silsiladaha isku xirka aan birta ah ee alxan lahayn waxaa lagu heli karaa cabbirro iyo qaabeyn kala duwan. Tani waxay kuu ogolaanaysaa habayn sahlan si loo daboolo baahiyahaaga gaarka ah waxayna hubisaa la jaanqaadida qalabkaaga jira.

Maalgashada silsiladaha alxanka leh ee birta-laxanka ah si aad u hesho xal la isku halayn karo oo hufan oo gudbintaada, qaadista iyo macdanta macdanta. Xooggeeda gaarka ah, adkeysigeeda iyo isku-bedelkeeda, silsiladani waxay wanaajin doontaa hawlgalkaaga, waxay siin doontaa waxqabad aan la qiyaasi karin waxayna hubin doontaa jawi shaqo oo badbaado leh.

Codsiga

Alaabooyinka La Xiriira

Qiyaasta Silsiladda

SCIC Round Link Chain waxaa loo sameeyay iyadoo loo eegayo heerka Shiinaha GB/T-12718 iyo shuruudaha farsamada, iyo sidoo kale DIN 22252 ama GOST 25996 heerarka iyo macaamiisha macaamiisha.

SCIC Round Link Chain waxa loo isticmaalaa Gaadhiyaasha Wajiga gaashaaman (AFC), Beam Stage Loaders (BSL), mishiinada madaxa wadada, marada dhuxusha iyo qalabka kale ee u baahan silsilad noocan ah.

Dahaarka ka-hortagga daxalka (tusaale, galvanization kulul) waxay keenaysaa hoos u dhaca guryaha makaanikada ah ee silsiladda, sidaa darteed codsashada dahaar kasta oo ka-hortagga dahaadhku waa in ay amar ku bixiyaan heshiis u dhexeeya iibsadaha iyo SCIC.

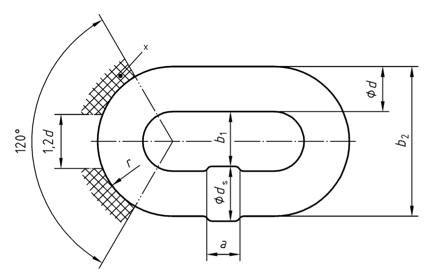

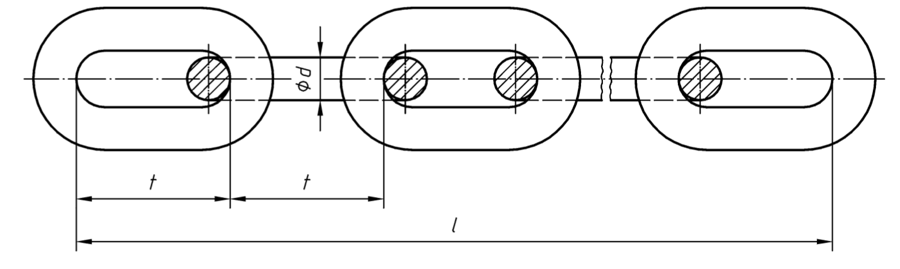

Jaantuska 1: silsilad isku xidhka wareega

Shaxda 1: cabbirka silsiladda isku xirka wareega

| cabbirka isku xirka (opp. Weld) | garoonka | ballaca isku xirka | cabbir alxanka link | miisaanka halbeegga | ||||

| magac ahaan | dulqaadasho | magac ahaan | dulqaadasho | gudaha | dibadda | dhexroorka | dhererka | |

| 10 | ± 0.4 | 40 | ±0.5 | 12 | 34 | 10.8 | 7.1 | 1.9 |

| 14 | ± 0.4 | 50 | ±0.5 | 17 | 48 | 15 | 10 | 4.0 |

| 18 | ± 0.5 | 64 | ±0.6 | 21 | 60 | 19.5 | 13 | 6.6 |

| 19 | ± 0.6 | 64.5 | ±0.6 | 22 | 63 | 20 | 13 | 7.4 |

| 22 | ± 0.7 | 86 | ±0.9 | 26 | 74 | 23.5 | 15.5 | 9.5 |

| 24 | ± 0.8 | 86 | ±0.9 | 28 | 79 | 26 | 17 | 11.6 |

| 26 | ± 0.8 | 92 | ±0.9 | 30 | 86 | 28 | 18 | 13.7 |

| 30 | ± 0.9 | 108 | ±1.1 | 34 | 98 | 32.5 | 21 | 18.0 |

| 34 | ± 1.0 | 126 | ±1.3 | 38 | 109 | 36.5 | 23.8 | 22.7 |

| 38 | ± 1.1 | 126 | ±1.3 | 42 | 121 | 41 | 27 | 30.1 |

| 38 | ± 1.1 | 137 | ±1.4 | 42 | 121 | 41 | 27 | 29.0 |

| 42 | ± 1.3 | 137 | ±1.4 | 48 | 137 | 45 | 30 | 36.9 |

| 42 | ± 1.3 | 146 | ±1.5 | 48 | 137 | 45 | 30 | 36.0 |

| 42 | ± 1.3 | 152 | ±1.5 | 46 | 133 | 45 | 30 | 35.3 |

| qoraalo: LSilsiladda cabbirka anger waa la heli karaa marka la weydiiyo. | ||||||||

Shaxda 2: silsilad isku xirka wareegyada guryaha farsamada

| cabbirka silsiladda | darajada silsiladda | xoog tijaabi | elongation hoos xoogga imtixaanka | xoog jabin | elongation at jab | leexashada ugu yar |

| 10 x 40 | S | 85 | 1.4 | 110 | 14 | 10 |

| SC | 100 | 1.6 | 130 | |||

| SCC | 130 | 1.9 | 160 | |||

| 14 x 50 | S | 150 | 1.4 | 190 | 14 | 14 |

| SC | 200 | 1.6 | 250 | |||

| SCC | 250 | 1.9 | 310 | |||

| 18 x 64 | S | 260 | 1.4 | 320 | 14 | 18 |

| SC | 330 | 1.6 | 410 | |||

| SCC | 410 | 1.9 | 510 | |||

| 19 x 64.5 | S | 290 | 1.4 | 360 | 14 | 19 |

| SC | 360 | 1.6 | 450 | |||

| SCC | 450 | 1.9 | 565 | |||

| 22 x 86 | S | 380 | 1.4 | 480 | 14 | 22 |

| SC | 490 | 1.6 | 610 | |||

| SCC | 610 | 1.9 | 760 | |||

| 24 x 86 | S | 460 | 1.4 | 570 | 14 | 24 |

| SC | 580 | 1.6 | 720 | |||

| SCC | 720 | 1.9 | 900 | |||

| 26 x 92 | S | 540 | 1.4 | 670 | 14 | 26 |

| SC | 680 | 1.6 | 850 | |||

| SCC | 850 | 1.9 | 1060 | |||

| 30 x 108 | S | 710 | 1.4 | 890 | 14 | 30 |

| SC | 900 | 1.6 | 1130 | |||

| SCC | 1130 | 1.9 | 1410 | |||

| 34 x 126 | S | 900 | 1.4 | 1140 | 14 | 34 |

| SC | 1160 | 1.6 | 1450 | |||

| SCC | 1450 | 1.9 | 1810kii | |||

| 38 x 126 | S | 1130 | 1.4 | 1420 | 14 | 38 |

| SC | 1450 | 1.6 | 1810kii | |||

| SCC | 1810kii | 1.9 | 2270 | |||

| 42 x 137 | S | 1390 | 1.4 | 1740kii | 14 | 42 |

| SC | 1770kii | 1.6 | 2220 | |||

| SCC | 2220 | 1.9 | 2770 |