Silsilad Kor U Qaadista Xidhiidhka Bir La'aanta Ah Oo wadata Shahaadada ISO ee Qalabka Rigging

Silsilad Kor U Qaadista Xidhiidhka Bir La'aanta Ah Oo wadata Shahaadada ISO ee Qalabka Rigging

Qaybta

Codsiga

Alaabooyinka La Xiriira

Silsiladda isku xidhka Parameter

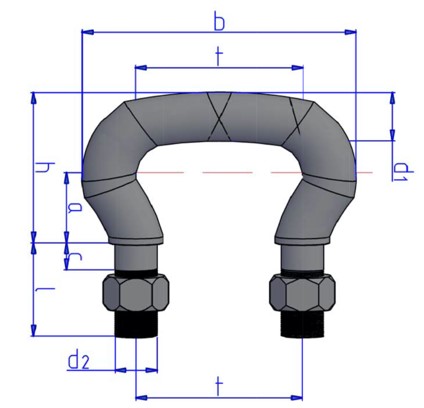

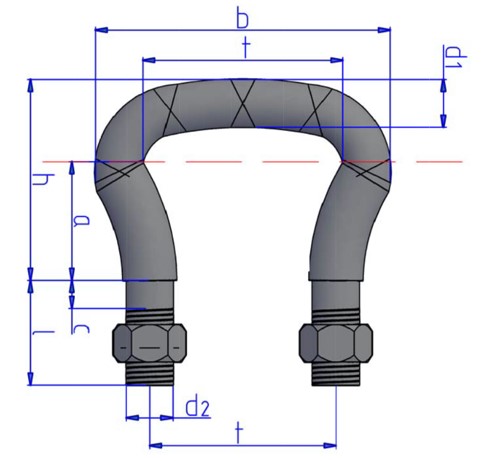

Jaantus 1: DIN 745 silsilad silsilad ah

Shaxda 1: DIN 745 cabbirka silsiladda silsiladda & sifooyinka farsamada

| Masaafada Masaafada | Silsiladda Shackle | Culayska jabinaya(kN) | |||||||||||

| t | m | w | s | d | t | a | b | c | d1 | d2 | h | l | |

| 45 | 75 | 30 | 5 | 10.5 | 45 | 20 | 73 | 8 | 11.5 | M10 | 40 | 25 | 76 |

| 56 | 95 | 40 | 6 | 13 | 56 | 25 | 92 | 10 | 15 | M12 | 50 | 32 | 112 |

| 63 | 110 | 40 | 6 | 17 | 63 | 30 | 105 | 10 | 18 | M16 | 60 | 40 | 142 |

| 70 | 120 | 50 | 6 | 21 | 70 | 34 | 116 | 12 | 20 | M20 | 68 | 45 | 176 |

| 80 | 130 | 50 | 6 | 21 | 80 | 37 | 132 | 12 | 23 | M20 | 74 | 45 | 230 |

| 91 | 150 | 60 | 8 | 25 | 91 | 43 | 149 | 14 | 26 | M24 | 86 | 55 | 300 |

| 105 | 165 | 60 | 8 | 25 | 105 | 50 | 173 | 14 | 30 | M24 | 100 | 55 | 395 |

| 126 | 200 | 70 | 10 | 31 | 126 | 59 | 206 | 18 | 36 | M30 | 118 | 70 | 570 |

| 147 | 220 | 70 | 10 | 31 | 147 | 68 | 239 | 22 | 42 | M30 | 136 | 70 | 775 |

DIN 745 silsilad silsilad ah (xeerka silsiladda) waa inuu ku habboon yahay silsiladda isku xirka birta wareegsan ee DIN 764 iyo DIN 766. Haddii ay dhacdo codsi adag oo adag, kiis adag (tusaale, carburization) ayaa la geynayaa si ay ula kulanto HRC 55-60.

Xakamaynta cabbirka, tijaabada xoogga jebinta iyo hubinta adkaanta waa in lagu dabaqaa qayb kasta oo ka mid ah wax soo saarka silsiladaha.

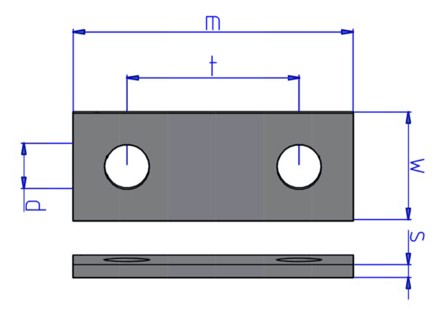

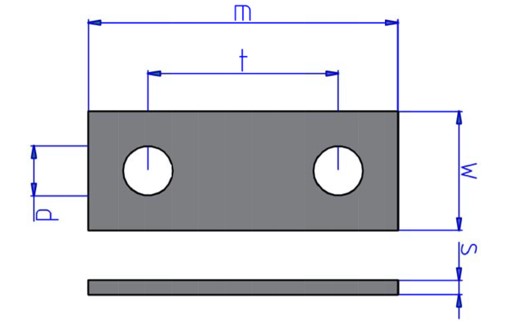

Jaantus 2: DIN 5699 silsilad silsilad ah

Shaxda 2: DIN 5699 cabbirka silsiladda silsiladda & sifooyinka farsamada

| Masaafada Masaafada | Silsiladda Shackle | Culayska jabinaya(kN) | |||||||||||

| t | m | w | s | d | t | a | b | c | d1 | d2 | h | l | |

| 45 | 75 | 30 | 5 | 13 | 45 | 28 | 75 | 8 | 15 | M12 | 53 | 30 | 86 |

| 56 | 95 | 40 | 6 | 15 | 56 | 34 | 92 | 10 | 18 | M14 | 64 | 35 | 127 |

| 63 | 110 | 40 | 6 | 17 | 63 | 37 | 105 | 10 | 21 | M16 | 71 | 40 | 167 |

| 70 | 120 | 50 | 6 | 21 | 70 | 42 | 116 | 12 | 23 | M20 | 80 | 45 | 203 |

| 80 | 130 | 50 | 6 | 21 | 80 | 47 | 132 | 12 | 26 | M20 | 89 | 45 | 264 |

| 91 | 150 | 60 | 8 | 25 | 91 | 52 | 149 | 14 | 29 | M24 | 99 | 55 | 332 |

| 105 | 165 | 60 | 8 | 25 | 105 | 60 | 173 | 14 | 34 | M24 | 114 | 55 | 450 |

| 126 | 200 | 70 | 10 | 31 | 126 | 71 | 206 | 18 | 40 | M30 | 134 | 65 | 635 |

| 136 | 220 | 80 | 12 | 37 | 136 | 76 | 224 | 22 | 44 | M36 | 146 | 75 | 757 |

| 147 | 230 | 80 | 12 | 37 | 147 | 81 | 241 | 22 | 47 | M36 | 157 | 75 | 871 |

DIN 745 silsilad silsilad ah (xeerka silsiladda) waa inuu ku habboon yahay silsiladda isku xirka birta wareegsan ee DIN 764 iyo DIN 766. Haddii ay dhacdo codsi adag oo adag, kiis adag (tusaale, carburization) ayaa la geynayaa si ay ula kulanto HRC 55-60.

Xakamaynta cabbirka, tijaabada xoogga jebinta iyo hubinta adkaanta waa in lagu dabaqaa qayb kasta oo ka mid ah wax soo saarka silsiladaha.

Silsilad nashqad gaar ah oo lagu xidho macmiil kasta