Isku xirka Wareegga Xannibaynta Sare 18mm Mining G80 Silsilad Gaaban

Isku xirka Wareegga Xannibaynta Sare 18mm Mining G80 Silsilad Gaaban

Qaybta

Codsiga

Alaabooyinka La Xiriira

Qiyaasta Silsiladda

Sida soo saaraha silsilad isku xidhka birta wareegsan muddo 30 sano ah, warshadeena ayaa la joogaya oo u adeegta muddada aad u muhiim ah silsilad Chinese samaynta horumarinta warshadaha cunto macdanta (mineed dhuxusha gaar ahaan), qaadista culus, iyo shuruudaha gudbinta warshadaha on xoog sare wareeg ah silsiladaha isku xirka birta. Kuma joogsanno inaan noqono hormuudka soo saaraha silsiladda wareegga wareegga ee Shiinaha (oo leh sahay sannadle ah oo ka badan 10,000T), laakiin ku dheggan abuurista aan joogsiga lahayn iyo hal-abuurka.

SCIC Round Link Chain waxaa loo sameeyay iyadoo loo eegayo heerka Shiinaha GB/T-12718 iyo shuruudaha farsamada, iyo sidoo kale DIN 22252 ama GOST 25996 heerarka iyo macaamiisha macaamiisha.

SCIC Round Link Chain waxa loo isticmaalaa Gaadhiyaasha Wajiga gaashaaman (AFC), Beam Stage Loaders (BSL), mishiinada madaxa wadada, marada dhuxusha iyo qalabka kale ee u baahan silsilad noocan ah.

Dahaarka ka-hortagga daxalka (tusaale, galvanization kulul) waxay keenaysaa hoos u dhaca guryaha makaanikada ah ee silsiladda, sidaa darteed codsashada dahaar kasta oo ka-hortagga dahaadhku waa in ay amar ku bixiyaan heshiis u dhexeeya iibsadaha iyo SCIC.

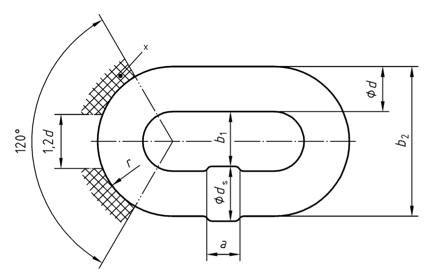

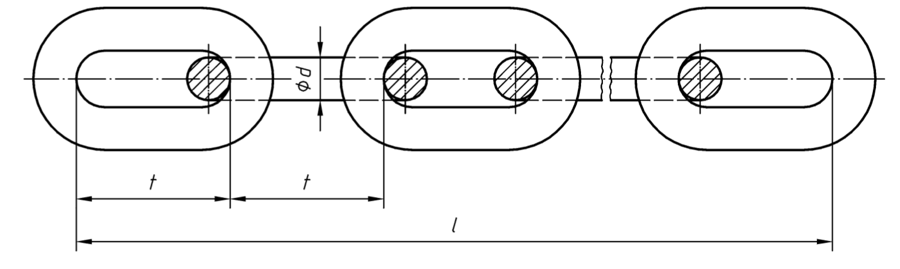

Jaantuska 1: silsilad isku xidhka wareega

Shaxda 1: cabbirka silsiladda isku xirka wareega

| cabbirka isku xirka (opp. Weld) | garoonka | ballaca isku xirka | cabbir alxanka link | miisaanka halbeegga | ||||

| magac ahaan | dulqaadasho | magac ahaan | dulqaadasho | gudaha | dibadda | dhexroorka | dhererka | |

| 10 | ± 0.4 | 40 | ±0.5 | 12 | 34 | 10.8 | 7.1 | 1.9 |

| 14 | ± 0.4 | 50 | ±0.5 | 17 | 48 | 15 | 10 | 4.0 |

| 18 | ± 0.5 | 64 | ±0.6 | 21 | 60 | 19.5 | 13 | 6.6 |

| 19 | ± 0.6 | 64.5 | ±0.6 | 22 | 63 | 20 | 13 | 7.4 |

| 22 | ± 0.7 | 86 | ±0.9 | 26 | 74 | 23.5 | 15.5 | 9.5 |

| 24 | ± 0.8 | 86 | ±0.9 | 28 | 79 | 26 | 17 | 11.6 |

| 26 | ± 0.8 | 92 | ±0.9 | 30 | 86 | 28 | 18 | 13.7 |

| 30 | ± 0.9 | 108 | ±1.1 | 34 | 98 | 32.5 | 21 | 18.0 |

| 34 | ± 1.0 | 126 | ±1.3 | 38 | 109 | 36.5 | 23.8 | 22.7 |

| 38 | ± 1.1 | 126 | ±1.3 | 42 | 121 | 41 | 27 | 30.1 |

| 38 | ± 1.1 | 137 | ±1.4 | 42 | 121 | 41 | 27 | 29.0 |

| 42 | ± 1.3 | 137 | ±1.4 | 48 | 137 | 45 | 30 | 36.9 |

| 42 | ± 1.3 | 146 | ±1.5 | 48 | 137 | 45 | 30 | 36.0 |

| 42 | ± 1.3 | 152 | ±1.5 | 46 | 133 | 45 | 30 | 35.3 |

| qoraalo: LSilsiladda cabbirka anger waa la heli karaa marka la weydiiyo. | ||||||||

Shaxda 2: silsilad isku xirka wareegyada guryaha farsamada

| cabbirka silsiladda | darajada silsiladda | xoog tijaabi | elongation hoos xoogga imtixaanka | xoog jabin | elongation at jab | leexashada ugu yar |

| 10 x 40 | S | 85 | 1.4 | 110 | 14 | 10 |

| SC | 100 | 1.6 | 130 | |||

| SCC | 130 | 1.9 | 160 | |||

| 14 x 50 | S | 150 | 1.4 | 190 | 14 | 14 |

| SC | 200 | 1.6 | 250 | |||

| SCC | 250 | 1.9 | 310 | |||

| 18 x 64 | S | 260 | 1.4 | 320 | 14 | 18 |

| SC | 330 | 1.6 | 410 | |||

| SCC | 410 | 1.9 | 510 | |||

| 19 x 64.5 | S | 290 | 1.4 | 360 | 14 | 19 |

| SC | 360 | 1.6 | 450 | |||

| SCC | 450 | 1.9 | 565 | |||

| 22 x 86 | S | 380 | 1.4 | 480 | 14 | 22 |

| SC | 490 | 1.6 | 610 | |||

| SCC | 610 | 1.9 | 760 | |||

| 24 x 86 | S | 460 | 1.4 | 570 | 14 | 24 |

| SC | 580 | 1.6 | 720 | |||

| SCC | 720 | 1.9 | 900 | |||

| 26 x 92 | S | 540 | 1.4 | 670 | 14 | 26 |

| SC | 680 | 1.6 | 850 | |||

| SCC | 850 | 1.9 | 1060 | |||

| 30 x 108 | S | 710 | 1.4 | 890 | 14 | 30 |

| SC | 900 | 1.6 | 1130 | |||

| SCC | 1130 | 1.9 | 1410 | |||

| 34 x 126 | S | 900 | 1.4 | 1140 | 14 | 34 |

| SC | 1160 | 1.6 | 1450 | |||

| SCC | 1450 | 1.9 | 1810kii | |||

| 38 x 126 | S | 1130 | 1.4 | 1420 | 14 | 38 |

| SC | 1450 | 1.6 | 1810kii | |||

| SCC | 1810kii | 1.9 | 2270 | |||

| 42 x 137 | S | 1390 | 1.4 | 1740kii | 14 | 42 |

| SC | 1770kii | 1.6 | 2220 | |||

| SCC | 2220 | 1.9 | 2770 |