Gaadhida Silsiladda xoqida foornada ee Mashiinnada Macdanta

Gaadhida Silsiladda xoqida foornada ee Mashiinnada Macdanta

Soo bandhigida Gaadhida Silsiladda Abrasion Forged ee Mashiinada Macdanta, xal goyn ah oo loogu talagalay in lagu beddelo warshadaha macdanta. Alaabta cusubi waxay isku daraysaa adkaysi aan caadi ahayn iyo isku halaynta, taas oo ka dhigaysa mid ku habboon hawlaha macdanta culus ee culus.

Gaadhiyaashayada silsilada xoqida ee been abuurka ah waxaa loo habeeyay inay u adkeystaan xaaladaha adag ee macdanta, iyagoo hubinaya waxqabadka aan kala go'in iyo nolosha adeega dheeradka. Waxaa lagu farsameeyay qalab tayo sare leh oo la been abuurtay. Tani waxay hubinaysaa awoodda ugu badan, adkeysiga iyo xirashada iska caabbinta, taasoo u oggolaanaysa inay u adkeysato jawiga macdanta ugu adag.

Alaabtu waxay ku qalabaysan tahay silsilad gaadiid qaada oo adag oo loo habeeyay dhaqdhaqaaqa hufan ee alaabta badan ee hawlaha macdanta. Silsilada macdanta waxaa loogu talagalay in si badbaado leh loogu qaado culeysyo culus masaafada dheer, yareynta waxtarka shaqada iyo sare u qaadida wax soo saarka. Nashqaddeeda gaarka ah waxay sidoo kale yaraynaysaa khatarta alaabta ku daadatay iyo waxyeellada dhinaca khadka qaada.

Badbaadada ayaa muhiim u ah hawlgal kasta oo macdan qodis ah iyo gaadiidleydayada silsiladaha xoqida ee been abuurka ah waxay la kulmaan heerarka badbaadada ee ugu sarreeya. Waxaa lagu qalabeeyay astaamo kala duwan oo nabdoon, oo ay ku jiraan habka daminta degdega ah iyo ilaalinta culeyska xad dhaafka ah, hubinta badbaadada qalabka iyo shaqaalaha u dhow.

Waxaa dheer, gaadiidleyda silsilada xoqida ee been abuurka ah waa sahlan tahay in la rakibo lana ilaaliyo. Naqshadeynta iyada oo maskaxda lagu hayo isticmaale-saaxiibtinimo, si fudud ayaa la isugu keeni karaa oo la kala diri karaa, hoos u dhigi karta wakhtiga dhimista iyo wanaajinta guud ahaan hufnaanta hawlgalka. Silsiladda gaadiidka qaada sidoo kale waa ay fududahay in la kormeero lana dayactiro, iyadoo sahlaysa dayactir degdeg ah oo aan dhib lahayn.

Gaadhiyaashayada silsilada xoqida ee been abuurka ah ayaa lagu heli karaa cabbirro kala duwan iyo qaabayn si loo daboolo baahiyaha gaarka ah ee codsiyada macdanta kala duwan. Haddii aad ku jirto qodista dhuxusha, macdanta dahabka ama hawlo kale oo macdan qodis ah, alaabtayada waxa loo habayn karaa si ay u buuxiyaan shuruudahaaga.

Gaadiidleyda AFC ee been abuurka ah ee makiinadaha macdanta, waxaad aamini kartaa in hawlahaaga macdan qodista lagu taageeri doono xalal la isku halayn karo, waxqabad sare leh. Nala soo xidhiidh maanta si aad wax badan uga barato sida badeecadaheenu u wanaajin karaan habka macdantaada oo ay u kordhiyaan wax soo saarkaaga.

Qaybta

Silsilad isku xidhka fidsan, silsilad isku xidhka fidsan macdanta macdanta, silsilada isku xidhka wareegta macdanta, DIN 22255 silsilado isku xidha fidsan oo loogu istcimaalayo gaadiidlayda joogtada ah ee macdanta

Codsiga

Gawaadhida Wajiga gaashaaman (AFC), Raadiyayaasha Heerka Beam (BSL),mashiinnada madaxa wadada

Silsiladda isku xirka nooca Flat ayaa markii ugu horreysay lagu soo bandhigay warshadaha macdanta by silsilad Jarmal ah oo dib u soo celisay 1985. Silsiladda isku xirka gurigu waxay ka kooban tahay iskuxiraha wareega (DIN 22252) laakiin isku xirka labaad ee kasta (xiriirka tooska ah) waa xiriiriye fidsan kaas oo dhinacyada toosan yihiin dhammayn siman oo siman DIN 22255 awgeed

Xidhiidhiyayaasha fidsan ee SCIC waa kuwo la been abuuray, lagana soo qaatay wax la mid ah kuwa isku xirka wareegsan.

Cabbir ahaan, aagga qaybta iskutallaabta toosan ee fidsan ayaa ka weyn kan isku xirka wareega ah. Marka silsiladda isku xidhka fidsan ee buuxa ay dhex marto daawaynta kulaylka nashqadeysan iyo kormeerka ugu dambeeya & tijaabada, sifooyinka farsamada ee isku xirka fidsan ayaa si wanaagsan loo dammaanad qaaday cabirka silsiladda iyo darajada loo qoondeeyay.

Silsiladda fidsan ee SCIC waxaa loo sameeyay iyadoo loo eegayo heerka Shiinaha MT/T-929 iyo Shuruudaha Farsamo ee warshadda, iyo sidoo kale DIN 22255 ama faahfaahinta macaamiisha (taas oo ah in si gaar ah loogu heshiiyo).

Silsiladda fidsan ee SCIC waxa loo isticmaalaa Gaadhiyaasha Wajiga gaashaaman (AFC), Beam Stage Loaders (BSL), mashiinnada madaxa wadada iyo qalabka kale ee u baahan silsilad noocan ah.

Dahaarka ka-hortagga daxalka (tusaale, galvanization kulul) waxay keenaysaa hoos u dhaca guryaha makaanikada ah ee silsiladda, sidaa darteed codsashada dahaar kasta oo ka-hortagga dahaadhku waa in ay amar ku bixiyaan heshiis u dhexeeya iibsadaha iyo SCIC.

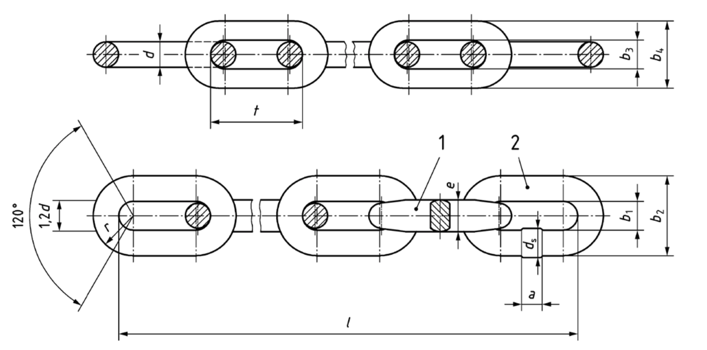

Jaantuska 1: Silsilad siman

Shaxda 1: cabbirrada silsiladda isku xirka fidsan

| cabbirka silsiladda | dhexroorka | ballac ahaan | garoonka | ballaca isku xirka wareega (mm) | ballaca isku xirka fidsan (mm) | miisaanka halbeegga | ||||

| magac ahaan | dulqaadasho | magac ahaan | dulqaadasho | gudahab1 | dibaddab2 | gudahab3 | dibadda b4 | |||

| 26 x 92 | 26 | ± 0.8 | 27 | 92 | ± 0.9 | 30 | 86 | 30 | 74 | 12.8 |

| 30 x 108 | 30 | ± 0.9 | 33 | 108 | ± 1.0 | 34 | 98 | 34 | 86 | 18.0 |

| 34 x 126 | 34 | ± 1.0 | 37 | 126 | ± 1.2 | 38 | 109 | 38 | 97 | 22.7 |

| 38 x 126 | 38 | ± 1.1 | 42 | 126 | ± 1.4 | 42 | 121 | 42 | 110 | 29.4 |

| 38 x 137 | 38 | ± 1.1 | 42 | 137 | ± 1.4 | 42 | 121 | 42 | 110 | 28.5 |

| 38 x 146 | 38 | ± 1.1 | 42 | 146 | ± 1.4 | 42 | 121 | 42 | 110 | 28.4 |

| 42 x 146 | 42 | ± 1.3 | 46 | 146 | ± 1.5 | 46 | 135 | 46 | 115 | 34.2 |

| 42 x 152 | 42 | ± 1.3 | 46 | 152 | ± 1.5 | 46 | 135 | 46 | 115 | 35.0 |

| qoraalo: silsilad cabbir weyn oo la heli karo marka la weydiiyo. | ||||||||||

Shaxda 2: Silsiladda siman ee isku xirka guryaha farsamada

| cabbirka silsiladda | darajada silsiladda | xoog tijaabi | elongation hoos xoogga imtixaanka | xoog jabin | elongation at jab | leexashada ugu yar |

| 26 x 92 | S | 540 | 1.4 | 670 | 11 | 26 |

| SC | 680 | 1.6 | 850 | |||

| 30 x 108 | S | 710 | 1.4 | 890 | 11 | 30 |

| SC | 900 | 1.6 | 1130 | |||

| 34 x 126 | S | 900 | 1.4 | 1140 | 11 | 34 |

| SC | 1160 | 1.6 | 1450 | |||

| 38 x 126 | S | 1130 | 1.4 | 1420 | 11 | 38 |

| SC | 1450 | 1.6 | 1810kii | |||

| 42 x 146 | S | 1390 | 1.4 | 1740kii | 11 | 42 |

| SC | 1770kii | 1.6 | 2220 | |||

| Fiiro gaar ah: leexintu maaha mid lagu dabaqi karo isku xirka fidsan ee been abuurka ah | ||||||