100kn Alloy Steel Link welded Lashing Lifting Mining Silsilad

100kn Alloy Steel Link welded Lashing Lifting Mining Silsilad

Soo bandhigida kacaankeena 100kn Alloy Steel Ring Welded Lashing Lifting Mining Chain, xalka ugu fiican ee dhammaan baahiyahaaga macdan qodista iyo kor u qaadista. Soo saarahayadu waa shirkaddayada aadka loo ixtiraamo oo hormuud u ahayd warshadaha 30 sano, waxaanu si joogto ah ula kulannaa baahida isbeddelka ee warshadaha wax soo saarka ee Shiinaha, gaar ahaan macdanta, qaadista culus iyo gudbinta warshadaha.

Giraantayada birta ah ee 100kn ee alxanka leh ee silsiladaha macdan qodista waxa loogu talagalay in ay u adkeysato xaaladaha ba'an oo ay siiso xoog aan la mid ahayn hawlaha macdanta adag. Ka samaysan bir tayo sare leh oo tayo sare leh, silsiladdu waa mid waara, hubinaysa adkeysiga iyo isku halaynta xitaa meelaha ugu adag. Awoodda culeyska ugu badan ee 100kn, waxay leedahay awood wax-qaadis aad u fiican waana aalad lagama maarmaan u ah hawlgallada culus ee qaadista.

Silsiladdu waxa ay ka kooban tahay xidhidhiyo dharbaaxo alxan leh oo ilaalin dheeraad ah marka la qaadayo rarka culculus, taas oo ku siinaysa xasilooni maskaxda ah in qalabkaaga iyo agabkaaguba si ammaan ah loo sugay. Xiriiriye kasta si taxadar leh ayaa loo qaabeeyey oo loo soo saaray si uu u buuxiyo oo uu dhaafo heerarka warshadaha ugu sarreeya, iyadoo la hubinayo badbaadada iyo waxtarka ugu badan inta lagu jiro hawlgalkaaga.

100kn Alloy Steel Ring Welded Lashing Lifting Mining Silsiladaha waa natiijada cilmi baarista iyo horumarinta sanado badan, isku darka tignoolajiyada gees ka gees leh aqoontayada iyo khibradeena ballaaran. Waxaan fahamsanahay caqabadaha gaarka ah ee wajahaya waaxyaha macdanta iyo warshadaha waxaana naga go'an inaan bixinno silsiladda ugu kalsoonida badan uguna waxqabadka badan si aan u daboolno shuruudahaaga gaarka ah.

Xaruntayada casriga ah, waxaanu ku shaqaynaa nidaam ilaalin tayo leh, anagoo hubinayna in silsilad kasta si fiican loo baadho ka hor intaanay ka tagin dhismahayaga. Ballanqaadkayaga xagga sareynta iyo ku qanacsanaanta macaamiisha ayaa nagu kaxaysa inaan bixinno alaabooyinka tayada ugu sarreeya ee si joogto ah u buuxiya kana sarreeya filashada warshadaha.

Maalgelinta 100kn Alloy Steel Giraanta Welded Lashing Lifting Mining Chain oo khibrad kala duwanaanshaha waxqabadka iyo isku halaynta Ku biir liiska dheer ee macaamiisha qanacsan ee nagu kalsoon macdan qodista & kor u qaadida baahidooda. Nala soo xidhiidh maanta si aad wax badan uga barato alaabtayada iyo sida aan kuugu caawin karno inaad gaarto yoolalkaaga. Aan noqono lammaanahaaga guuleysta.

Qaybta

Silsiladda isku xirka wareega, silsilad isku xirka birta wareega, silsilada isku xirka macdanta wareega, DIN 22252silsilad macdanta, silsilad conveyor macdanta, nidaamka silsilad bar duulimaadka

Codsiga

Gawaadhida Wajiga Gaashaan (AFC), Beam Stage Loaders (BSL), mashiinada madaxa wadada, jeexyada dhuxusha, iwm.

Sida No. 1 dalka wax soo saarka dhuxusha, Shiinaha ayaa arkay baahida loo qabo tiro weyn oo wareeg ah silsiladaha macdanta isku xidha, oo sidaas ayaa dhiiri Shiinaha wareeg ah awoodda wax soo saarka silsilad birta ah marka la eego tirada iyo tayada. Warshada silsiladda SCIC oo leh 30 sano oo silsilad silsilado bir ah oo wareeg ah taariikhda wax soo saarka ayaa si buuxda ugu lug lahayd sahayda warshadaha dhuxusha ee Shiinaha; Silsiladayada isku xirka wareega ah ayaa ilaa hadda si wanaagsan loo aqbalay oo ay isticmaaleen dhammaan shirkadaha dhuxusha & macdanta ee Shiinaha.

Tayada silsiladeena isku xirka birta wareega ah waxaa lagu hubiyaa tillaabo kasta oo wax soo saarka silsiladda, laga bilaabo baararka birta daawaha ee dhawaaqa si sax ah loo sameeyo isku xirka robot, laga bilaabo alxanka dabada kombuyuutarka ilaa si fiican loo demiyo & kuleylka kuleylka-daawaynta (taasoo keentay xoogga la doonayo iyo adkaanta dusha sare), laga bilaabo tijaabada caddaynta ilaa tijaabooyinka farsamada ee xaqiijinta tayada gudaha iyo sare.

Silsiladda wareegga wareegga SCIC waxaa loo sameeyay iyadoo loo eegayo heerka Shiinaha GB/T-12718 iyo Shuruudaha Farsamo ee warshadda, iyo sidoo kale DIN 22252 ama GOST 25996 heerarka iyo macaamiisha macaamiisha.

Silsiladda isku xirka wareega wareega ee SCIC waxaa loo adeegsadaa Conveyors Wajiga Gaashaan (AFC), Beam Stage Loaders (BSL), mashiinada madaxa wadada, jeexyada dhuxusha iyo qalabka kale ee u baahan silsilad noocan ah.

Dahaarka ka-hortagga daxalka (tusaale, galvanization kulul) waxay keenaysaa hoos u dhaca guryaha makaanikada ah ee silsiladda, sidaa darteed codsashada dahaar kasta oo ka-hortagga dahaadhku waa in ay amar ku bixiyaan heshiis u dhexeeya iibsadaha iyo SCIC.

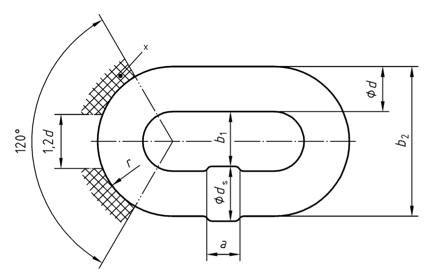

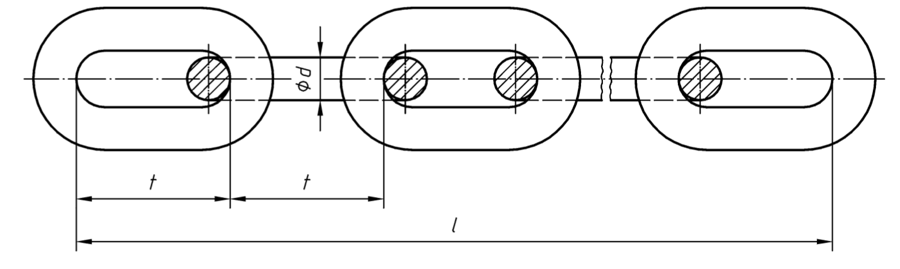

Jaantuska 1: silsilad isku xidhka wareega

Shaxda 1: cabbirka silsiladda isku xirka wareega

| cabbirka isku xirka (opp. Weld) | garoonka | ballaca isku xirka | cabbir alxanka link | miisaanka halbeegga | ||||

| magac ahaan | dulqaadasho | magac ahaan | dulqaadasho | gudaha | dibadda | dhexroorka | dhererka | |

| 10 | ± 0.4 | 40 | ±0.5 | 12 | 34 | 10.8 | 7.1 | 1.9 |

| 14 | ± 0.4 | 50 | ±0.5 | 17 | 48 | 15 | 10 | 4.0 |

| 18 | ± 0.5 | 64 | ±0.6 | 21 | 60 | 19.5 | 13 | 6.6 |

| 19 | ± 0.6 | 64.5 | ±0.6 | 22 | 63 | 20 | 13 | 7.4 |

| 22 | ± 0.7 | 86 | ±0.9 | 26 | 74 | 23.5 | 15.5 | 9.5 |

| 24 | ± 0.8 | 86 | ±0.9 | 28 | 79 | 26 | 17 | 11.6 |

| 26 | ± 0.8 | 92 | ±0.9 | 30 | 86 | 28 | 18 | 13.7 |

| 30 | ± 0.9 | 108 | ±1.1 | 34 | 98 | 32.5 | 21 | 18.0 |

| 34 | ± 1.0 | 126 | ±1.3 | 38 | 109 | 36.5 | 23.8 | 22.7 |

| 38 | ± 1.1 | 126 | ±1.3 | 42 | 121 | 41 | 27 | 30.1 |

| 38 | ± 1.1 | 137 | ±1.4 | 42 | 121 | 41 | 27 | 29.0 |

| 42 | ± 1.3 | 137 | ±1.4 | 48 | 137 | 45 | 30 | 36.9 |

| 42 | ± 1.3 | 146 | ±1.5 | 48 | 137 | 45 | 30 | 36.0 |

| 42 | ± 1.3 | 152 | ±1.5 | 46 | 133 | 45 | 30 | 35.3 |

| qoraalo:LSilsiladda cabbirka anger waa la heli karaa marka la weydiiyo. | ||||||||

Shaxda 2: silsilad isku xirka wareegyada guryaha farsamada

| cabbirka silsiladda | darajada silsiladda | xoog tijaabi | elongation hoos xoogga imtixaanka | xoog jabin | elongation at jab | leexashada ugu yar |

| 10 x 40 | S | 85 | 1.4 | 110 | 14 | 10 |

| SC | 100 | 1.6 | 130 | |||

| SCC | 130 | 1.9 | 160 | |||

| 14 x 50 | S | 150 | 1.4 | 190 | 14 | 14 |

| SC | 200 | 1.6 | 250 | |||

| SCC | 250 | 1.9 | 310 | |||

| 18 x 64 | S | 260 | 1.4 | 320 | 14 | 18 |

| SC | 330 | 1.6 | 410 | |||

| SCC | 410 | 1.9 | 510 | |||

| 19 x 64.5 | S | 290 | 1.4 | 360 | 14 | 19 |

| SC | 360 | 1.6 | 450 | |||

| SCC | 450 | 1.9 | 565 | |||

| 22 x 86 | S | 380 | 1.4 | 480 | 14 | 22 |

| SC | 490 | 1.6 | 610 | |||

| SCC | 610 | 1.9 | 760 | |||

| 24 x 86 | S | 460 | 1.4 | 570 | 14 | 24 |

| SC | 580 | 1.6 | 720 | |||

| SCC | 720 | 1.9 | 900 | |||

| 26 x 92 | S | 540 | 1.4 | 670 | 14 | 26 |

| SC | 680 | 1.6 | 850 | |||

| SCC | 850 | 1.9 | 1060 | |||

| 30 x 108 | S | 710 | 1.4 | 890 | 14 | 30 |

| SC | 900 | 1.6 | 1130 | |||

| SCC | 1130 | 1.9 | 1410 | |||

| 34 x 126 | S | 900 | 1.4 | 1140 | 14 | 34 |

| SC | 1160 | 1.6 | 1450 | |||

| SCC | 1450 | 1.9 | 1810kii | |||

| 38 x 126 | S | 1130 | 1.4 | 1420 | 14 | 38 |

| SC | 1450 | 1.6 | 1810kii | |||

| SCC | 1810kii | 1.9 | 2270 | |||

| 42 x 137 | S | 1390 | 1.4 | 1740kii | 14 | 42 |

| SC | 1770kii | 1.6 | 2220 | |||

| SCC | 2220 | 1.9 | 2770 |